Wellbore Heat Transport - EUBHE

Problem description

Ramey et al. (1962) proposed the analytical solution concerning the wellbore heat transmission, which can be used to quantify the fluid temperature change in the wellbore.

In order to verify the single pipe flow model in the OGS, the numerical results were compared with Ramey’s analytical solution Ramey et al. (1962).

The detailed calculation of the Ramey’s analytical solution is given below.

A detailed analysis of an enhanced U-tube borehole heat exchanger (EUBHE) can be found in Chen, C. et al. (2021).

Model Setup

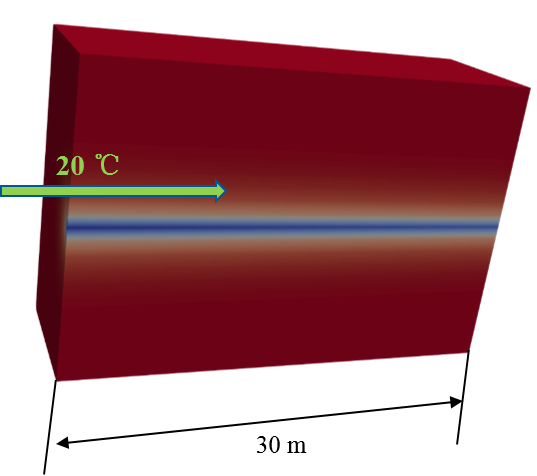

In this benchmark, the length of the wellbore is 30 m as shown in Figure 1 and the cold water is injected into the inlet point of the wellbore with the constant temperature of 20°C.

The initial temperature of the fluid and grout in the wellbore is 20 $^{\circ}$C, and temperature of the surrounding rock is 55 $^{\circ}$C.

The wellbore and pipe diameter are 0.28 m and 0.25826 m, respectively.

And the flow rate is 0.0002 $m^3/s$.

Figure 1: Single pipe flow model

# Import required libraries

import numpy as np

import matplotlib.pyplot as plt

import pandas as pdRamey’s analytical solution

The equations are followed by their implementation in python.

# Define constants

T_d = 55 # Temperature of undistributed formation

T_i = 20 # Temperature of inlet fluid

Z = np.insert(np.linspace(0.3,30,100), 0, 1e-10) # Depth below surface, start with very small value to prevent division by zero

q = 0.0002 # Flow rate of fluid in wellbore, m3/s

rho_f = 1000 # Density of fluid, unit kg/m3

c_p_f = 4190 # Specific heat capacity of fluid in wellbore

mu_f = 1.14e-3 # Unit kg/m/s;

lambda_f = 0.59 # Unit W/m/K

rho_re = 1800 # Density of geothermal reservoir

c_p_re = 1778 # Specific heat capacity of geothermal reservoir

lambda_re = 2.78018 # Heat conductivity coefficient of geothermal reservoir

lambda_g = 0.73 # Heat conductivity coefficient of grout and pipe

lambda_pi = 1.3

r_pi = 0.12913 # Inner radius of pipe and wellbore

r_b = 0.14

t_pi = 0.00587 # Thickness of the pipe

t = 86400 * 5 # Operation timeIn Ramey’s analytical solution Ramey et al. (1962), the outlet temperature of the pipe inside the wellbore can be calculated by

$$ T_o(t) = T_{s} + (T_i(t) - T_{s})\exp(-\Delta z/X) $$def temp(T_d, T_i, delta_z, X):

return T_d + (T_i - T_d) * np.exp(-delta_z / X)The coefficient $X$ is determined by

$$ X = \frac{q\rho_fc_{p,f}(\lambda_{s}+r_pUf(t))}{2\pi r_pU \lambda_{s}} $$where $q$ is the flow rate of the fluid in the wellbore.

def coefficient_x(q, rho_f, c_p_f, lambda_re, r_pi, U, f_t):

return (q * rho_f * c_p_f) * (lambda_re + r_pi * U * f_t) / (2 * np.pi * r_pi * U * lambda_re)With dimensionless time

$$ t_D = \frac{\lambda_{s}t}{(\rho_{s}c_{p,s}r_b^{2})} $$def dimless_t(lambda_re, delta_t, rho_re, c_p_re, r_b):

return lambda_re * delta_t / (rho_re * c_p_re * r_b * r_b)the time function $f(t)$ can be calculated by

$$ f(t) = [0.4063+0.5\ln(t_D)][1+\frac{0.6}{t_D}], t_D > 1.5 $$ $$ f(t) = 1.1281\sqrt{t_D}(1-0.3\sqrt{t_D}), t_D \leqslant 1.5 $$def time_function(t_D):

if t_D > 1.5:

f_t = (0.4063 + 0.5 * np.log(t_D)) * (1 + 0.6 / t_D)

else:

f_t = 1.1281 * np.sqrt(t_D) * (1 - 0.3 * np.sqrt(t_D))

return f_tThe Prandtl and Reynolds number can be calculated as follows

$$ \mathrm{Pr} = \frac{\mu_f c_{p,f}}{\lambda_f} $$ $$ \mathrm{Re} = \frac{\rho_f v d_{pi}}{\mu_f} $$where, $\mu_f, \rho_f$ and $\lambda_f$ is the fluid viscosity, density and thermal conductivity.

# Calculate the convective film resistance inside pipe

v = q / (np.pi * r_pi * r_pi)

# Reynolds number

Pr = mu_f * c_p_f / lambda_f

Re = rho_f * v * (2 * r_pi) / mu_fThe Nusselt number can be determined by the following equation Diersch, (2011):

$$ \mathrm{Nu} = 4.364,\ \mathrm{Re} < 2300 $$ $$ \mathrm{Nu} = \frac{(\xi_{k}/8)\ \mathrm{Re}_{k}\ \mathrm{Pr}}{1+12.7\sqrt{{\xi_k}/8}(\mathrm{Pr}^{2/3}-1)} [ 1+(\frac{{d_k}^{i}}{L})^{2/3}], Re \geq 10^4 $$ $$ \mathrm{Nu} = (1-\gamma_{k})\ 4.364 + \gamma_{k} ( \frac{(0.0308/8)10^{4}\mathrm{Pr}}{1+12.7\ \sqrt{0.0308/8}(\mathrm{Pr}^{2/3}-1)} \left[ 1+\left(\frac{d_{k}^{i}}{L}\right)^{2/3} \right] ), 2 300 \leq \mathrm{Re} < 10^{4} $$with

$$ \xi_{k}=(1.8\ \log_{10}\mathrm{Re}_{k}-1.5)^{-2} $$and

$$ \gamma_{k} = \frac{\mathrm{Re}_{k}-2300}{10^{4}-2300} $$# Estimate convective film coefficient

xi = (1.8 * np.log(Re) - 1.5)**(-2)

Nu_l = (xi / 8.0 * Re * Pr) / (1.0 + 12.7 * np.sqrt(xi / 8.0) * ((Pr)**(2.0 / 3.0) - 1.0)) * (1.0 + (r_pi / Z)**(2.0 / 3.0))

Nu_lam = 4.364

gamma = (Re - 2300) / (10000 - 2300)

Nu_m = (1.0 - gamma) * 4.364 + gamma * ((0.0308 / 8.0 * 1.0e4 * Pr) / (1.0 + 12.7 * np.sqrt(0.0308 / 8.0) * ((Pr)**(2.0 / 3.0) - 1.0)) * (1.0 + (r_pi / Z)**(2.0 / 3.0)))

# Evaluate Nusselt number; based on the value of Re choose appropriate correlation

if Re < 2300:

Nu_p = Nu_lam

elif Re > 10000:

Nu_p = Nu_l

else:

Nu_p = Nu_mand the overall heat transfer coefficient $U$ is written as follows,

$$ U = [\frac{r_{pi}+t_{pi}}{r_{pi}h}+(r_{pi}+t_{pi})(\frac{\ln{\frac{r_{pi}+t_{pi}}{r_{pi}}}}{\lambda_{pi}}+\frac{\ln{\frac{r_b}{r_{pi}+t_{pi}}}}{\lambda_{grout}})]^{-1} $$with

$$ h = \frac{\lambda_f Nu}{2r_{pi}} $$h = lambda_f * Nu_p / (2 * r_pi) # Unit: W/m2/K

U = 1 / (((r_pi + t_pi) / (r_pi * h)) + (r_pi + t_pi) * (np.log((r_pi + t_pi) / r_pi) / lambda_pi + np.log(r_b / (r_pi + t_pi)) / lambda_g))The friction factor $f$, is evaluated by Churchill correlation Churchill et al. (1977),

$$ f = \frac{1}{(\frac{1}{[((\frac{8}{Re})^{10}+(\frac{Re}{36500})^{20})]^{1/2}}+[2.21(\ln{\frac{Re}{7}})]^{10})^{1/5}} $$# Churchill correlation for friction factor

f = 1 / ((1 / (np.sqrt((8 / Re) ** 10 + (Re / 36500) ** 20))) + (2.21 * np.log(Re / 7)) ** 10) ** (1 / 5)With these equations the analytical solution can be computed:

# Compute solution

time_range = range(0, t+1, 43200)

# Create a dataframe to store results for different z- and t-steps

row_names = Z

column_names = time_range

df = pd.DataFrame(index=row_names, columns=column_names)

for delta_z in Z:

T_0 = []

for delta_t in time_range:

# Compute dimensionless time

t_D = dimless_t(lambda_re, delta_t, rho_re, c_p_re, r_b)

# Compute time function

f_t = time_function(t_D)

# Compute X

X = coefficient_x(q, rho_f, c_p_f, lambda_re, r_pi, U, f_t)

# Compute outlet temperature

T_0.append(temp(T_d, T_i, delta_z, X))

df.loc[delta_z] = T_0Numerical solution

# Create output path

import os

from pathlib import Path

out_dir = Path(os.environ.get("OGS_TESTRUNNER_OUT_DIR", "_out"))

if not out_dir.exists():

out_dir.mkdir(parents=True)from ogs6py.ogs import OGS

# Create an OGS-object

# Pass the project file and set an output file path

model=OGS(INPUT_FILE="BHE_1P.prj", PROJECT_FILE=f"{out_dir}/BHE_1P.prj")

# set end time (in seconds) and the time increments

model.replace_text(5 * 24 * 60 * 60, xpath="./time_loop/processes/process/time_stepping/t_end")

model.replace_text(30, xpath="./time_loop/processes/process/time_stepping/timesteps/pair/repeat")

model.replace_text(4 * 60 * 60, xpath="./time_loop/processes/process/time_stepping/timesteps/pair/delta_t")

# Write to the output file

model.write_input()

# Run OGS

model.run_model(logfile=os.path.join(out_dir, "log.txt"), args=f"-o {out_dir} -m .")OGS finished with project file /var/lib/gitlab-runner/builds/F1XUyv4cx/0/ogs/build/release-all/Tests/Data/Parabolic/T/BHE_1P/pipe_flow_ebhe/BHE_1P.prj.

Execution took 85.03100848197937 s

Project file written to output.

Results and discussion

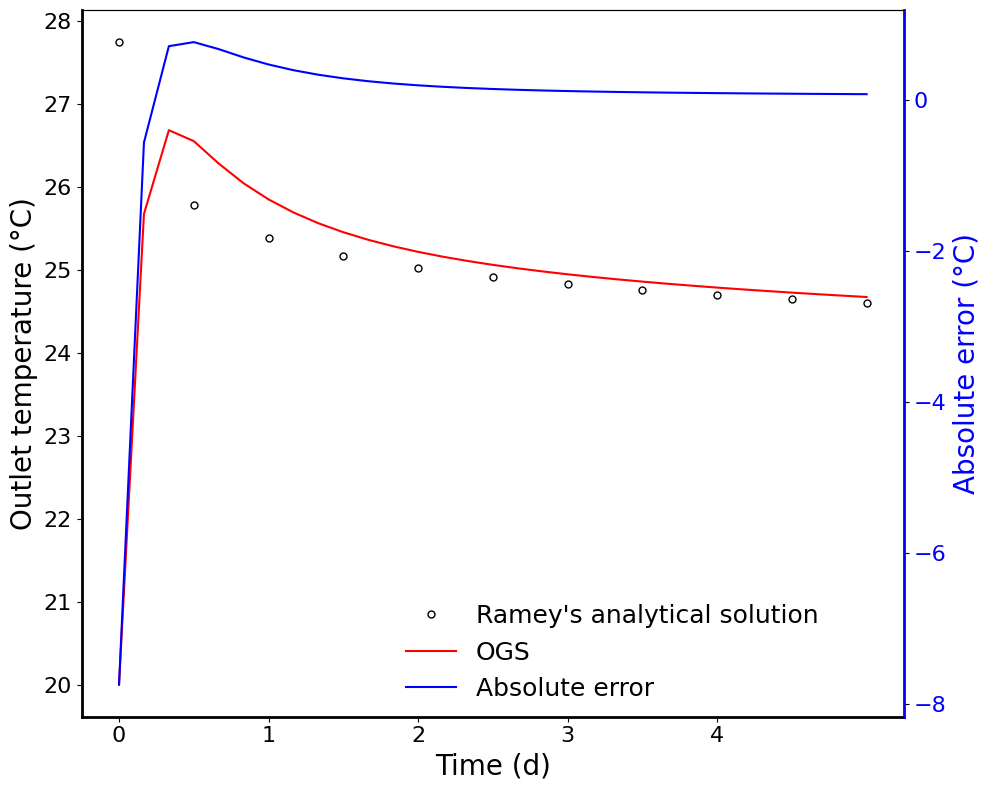

The outlet temperature change over time was compared against the analytical solution and presented in Figure 2.

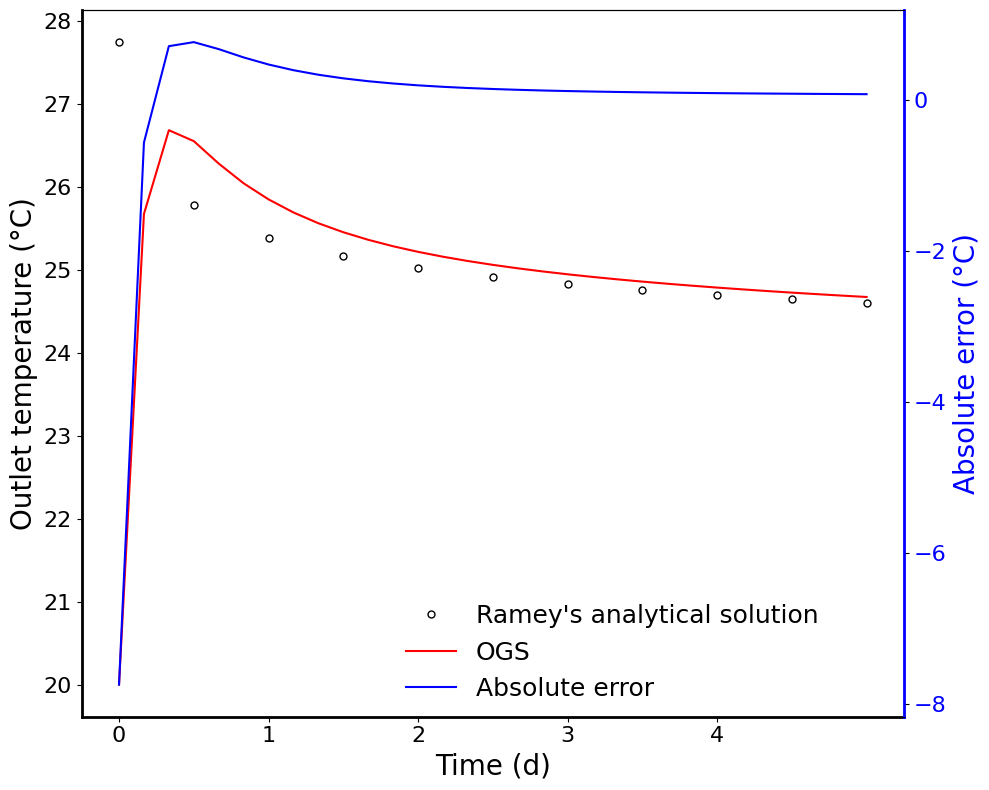

After 30 days, the fluid temperature distribution in the wellbore is shown in Figure 3.

The maximum relative error between the numerical model and Ramey’s analytical solution is less than 0.15%.

In numerical model, the outlet temperature at beginning stage is affected by the initial temperature in the pipe inside the wellbore.

The initial fluid temperature set in the benchmark means there is water with 20°C filled in the wellbore already before injecting water into the wellbore.

But in the analytical solution, no initial temperature is set and the temperature keeps equilibrium state at every moment.

The impact of initial temperature condition in numerical model is decreasing with the increasing of the operational time as shown in Figure 2.

import vtuIO

import numpy as np

import os

out_dir = os.environ.get('OGS_TESTRUNNER_OUT_DIR', '_out')

# Load the result

pvdfile = vtuIO.PVDIO(f"{out_dir}/BHE_1P.pvd", dim=3)

# Get point field names

fields = pvdfile.get_point_field_names()

print(fields)

# Get all written timesteps

time = pvdfile.timesteps

# Define observation points

observation_points = {'outlet':(0.0,10.0,-30.0)}

# Read the time series of point field 'temperature_BHE1'

temperature_BHE1 = pvdfile.read_time_series('temperature_BHE1', observation_points)WARNING: Default interpolation backend changed to VTK. This might result in

slight changes of interpolated values if defaults are/were used.

['temperature_BHE1', 'temperature_soil']

# Compute analytical solution again but at timesteps of numerical solution for error calculation

for delta_z in Z:

T_0 = []

for delta_t in time:

# Compute dimensionless time

t_D = dimless_t(lambda_re, delta_t, rho_re, c_p_re, r_b)

# Compute time function

f_t = time_function(t_D)

# Compute X

X = coefficient_x(q, rho_f, c_p_f, lambda_re, r_pi, U, f_t)

# Compute outlet temperature

T_0.append(temp(T_d, T_i, delta_z, X))# Plot numerical vs. analytical result

fig, ax1 = plt.subplots(figsize=(10, 8))

x_pos = np.arange(0, 432000, 60*60*24)

x_ticks = np.arange(0,5,1)

ax1.plot(time_range, df.iloc[-1, :], 'k.', markersize=10, markerfacecolor='none', label = 'Ramey\'s analytical solution')

ax1.plot(time, temperature_BHE1['outlet'][:,0], 'r', label = 'OGS')

ax1.set_ylabel('Outlet temperature (°C)', fontsize=20)

ax1.set_xlabel('Time (d)', fontsize=20)

ax1.set_xticks(x_pos, x_ticks)

ax1.spines['left'].set_linewidth(2)

ax1.spines['bottom'].set_linewidth(2)

ax1.tick_params(axis='both', labelsize=16)

color = 'blue'

ax2 = ax1.twinx()

ax2.plot(time ,temperature_BHE1['outlet'][:,0]-T_0, color=color, label = 'Absolute error')

ax2.set_ylabel('Absolute error (°C)', color=color, fontsize = 20)

ax2.tick_params(axis='y', labelcolor=color)

ax2.spines['right'].set_color('blue')

ax2.spines['right'].set_linewidth(2)

ax2.tick_params(axis='y', labelsize=16)

plt.figlegend(fontsize=18, loc = (0.4, 0.1), frameon=False)

fig.tight_layout()

plt.show()

Figure 2: Comparison with analytical solution results

# Extract values along a line in the domain

# Space axis for plotting

length = np.linspace(0, -30, 101)

# Draws a line through the domain for sampling results

x_axis=[(0,10,i) for i in length]

# At timestep i

i = -1

temp = pvdfile.read_set_data(time[i], "temperature_BHE1", pointsetarray=x_axis)

# Plot

fig, ax1 = plt.subplots(figsize=(10, 8))

ax1.set_xlabel('Distance (m)', fontsize = 20)

ax1.set_ylabel('Temperature (°C)', fontsize = 20)

ax1.plot(np.linspace(0,30,101), temp[:,0], 'r', linewidth = 2, label = 'OGS')

ax1.plot(Z,df.iloc[:, -1],'k.', markersize=10, markerfacecolor='none', label = 'Ramey\'s analytical solution')

ax1.set_ylim(19,25)

ax1.set_xlim(0,30)

ax1.spines['left'].set_linewidth(2)

ax1.spines['bottom'].set_linewidth(2)

ax1.tick_params(axis='both', labelsize=16)

color = 'blue'

ax2 = ax1.twinx()

ax2.set_ylabel('Absolute error (°C)', color=color, fontsize = 20)

ax2.plot(np.linspace(0,30,101), temp[:,0]-df.iloc[:, -1], linewidth = 2, color=color, label = 'Absolute error')

ax2.tick_params(axis='y', labelcolor=color)

ax2.spines['right'].set_color('blue')

ax2.spines['right'].set_linewidth(2)

ax2.tick_params(axis='y', labelsize=16)

fig.tight_layout()

plt.figlegend(fontsize=18, loc = (0.4, 0.1), frameon=False)

plt.show()

max_error = 0.08

if np.max(np.abs(temp[:,0]-df.iloc[:, -1])) > max_error:

raise RuntimeError(f'The maximum temperature error is over {max_error} °C, which is higher than expected')

Figure 3: Distributed temperature of fluid and absolute error.

References

[1] Ramey Jr, H. J. (1962). Wellbore heat transmission. Journal of petroleum Technology, 14(04), 427-435.

[2] Diersch, H-JG, et al. (2011). “Finite element modeling of borehole heat exchanger systems: Part 1. Fundamentals.” Computers & Geosciences 37.8, 1122-1135.

[3] Chaofan Chen, Wanlong Cai, Dmitri Naumov, Kun Tu, Hongwei Zhou, Yuping Zhang, Olaf Kolditz, Haibing Shao (2021). Numerical investigation on the capacity and efficiency of a deep enhanced U-tube borehole heat exchanger system for building heating. Renewable Energy, 169, 557-572.

[4] Churchill, S. W. (1977). Comprehensive correlating equations for heat, mass and momentum transfer in fully developed flow in smooth tubes. Industrial & Engineering Chemistry Fundamentals, 16(1), 109-116.

This article was written by Chaofan Chen, Haibing Shao, Frieder Loer. If you are missing something or you find an error please let us know.

Generated with Hugo 0.122.0

in CI job 449919

|

Last revision: August 3, 2023