Power Law Linear Creep

Power Law Linear Creep

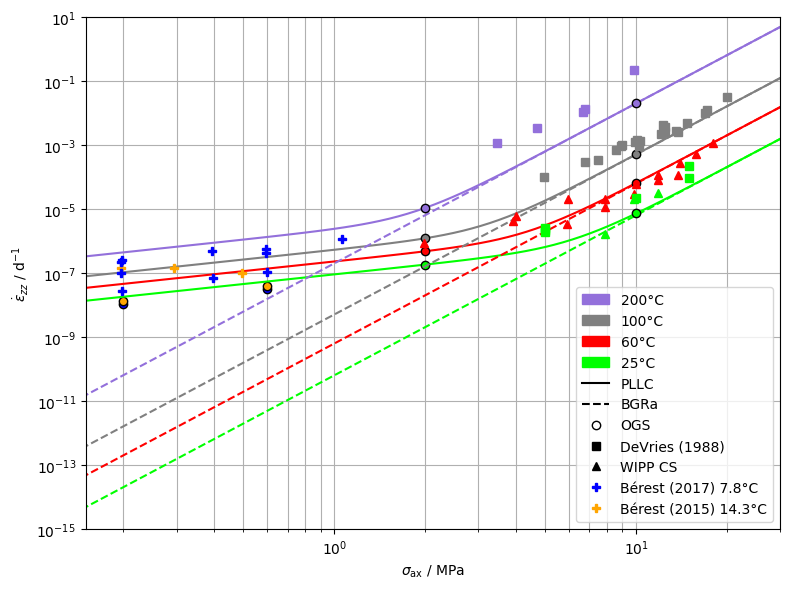

This benchmark shows the increased creep rate of salt rock at lower deviatoric stress. A two component power law (which we call Power Law Linear Creep, or short PLLC) provides an easy way to capture the power law behaviour (dislocation creep) and the linear behaviour (pressure solution creep). For more details have a look at (Zill et al., 2022).

import contextlib

import os

from pathlib import Path

import matplotlib as mpl

import matplotlib.pyplot as plt

import numpy as np

import vtuIO

from ogs6py import ogs

prj_name = "uniax_compression"

data_dir = os.environ.get(

"OGS_DATA_DIR", str(str(Path.cwd())).split("/Data/")[0] + "/Data/"

)

input_file = f"{data_dir}/Mechanics/PLLC/{prj_name}.prj"

from pathlib import Path

out_dir = Path(os.environ.get("OGS_TESTRUNNER_OUT_DIR", "_out"))

if not out_dir.exists():

out_dir.mkdir(parents=True)

os.chdir(out_dir)

prj_file = f"{out_dir}/{prj_name}_out.prj"

ogs_model = ogs.OGS(INPUT_FILE=input_file, PROJECT_FILE=prj_file)Experimental data

A nice overview for the strain rates of salt for different temperatures and differential stresses can be found in (Li et al., 2021).

# Unfortunately the source for the WIPP data has gone missing - will be added if it's found again

ExData = {

"WIPP CS 25": (

25,

"^",

[

[9.87970002, 2.013560846e-05],

[11.84642707, 3.178356756e-05],

[7.87388785, 1.66059726e-06],

],

),

"WIPP CS 60": (

60,

"^",

[

[3.98589289, 5.7824853e-06],

[5.94266985, 2.075776623e-05],

[7.87388785, 1.953209818e-05],

[9.96978837, 5.841438703e-05],

[11.84642707, 0.00011762092257],

[13.94911482, 0.00026749321794],

[17.9857158, 0.00111804208073],

[1.9814251, 8.7645834e-07],

[3.91418422, 4.01350889e-06],

[5.88897108, 3.34371363e-06],

[7.87388785, 1.129440706e-05],

[9.87970002, 2.99068674e-05],

[11.84642707, 7.681792203e-05],

[13.82306874, 0.00011067584933],

[15.83934389, 0.00052247037957],

],

),

"DeVries 1988 25": (

25,

"s",

[

[4.99, 2.10816e-06],

[4.99, 2.4192e-06],

[5, 1.8144e-06],

[9.99, 2.2032e-05],

[14.96, 9.2448e-05],

[14.98, 0.000216],

],

),

"DeVries 1988 100": (

100,

"s",

[

[4.95, 9.6768e-05],

[6.77, 0.000292896],

[7.46, 0.000324],

[8.55, 0.000664416],

[8.92, 0.00091584],

[8.98, 0.0009936],

[9.91, 0.00124416],

[10.1, 0.00139968],

[10.22, 0.00093312],

[10.27, 0.00132192],

[12.1, 0.00216],

[12.3, 0.00409536],

[12.35, 0.00320544],

[12.37, 0.00292032],

[12.39, 0.00253152],

[12.4, 0.0026784],

[12.46, 0.0025056],

[12.49, 0.00347328],

[13.57, 0.00273024],

[13.78, 0.00242784],

[14.7, 0.00482112],

[16.87, 0.0095904],

[17.2, 0.0123552],

[19.96, 0.030672],

],

),

"DeVries 1988 200": (

200,

"s",

[

[3.47, 0.00117504],

[4.71, 0.0032832],

[6.67, 0.0104544],

[6.78, 0.0132192],

[9.86, 0.214272],

],

),

"Berest 2015 14.3": (

14.3,

"P",

[

[0.09909639, 8.944207e-08],

[0.19575886, 1.4118213e-07],

[0.29452325, 1.4118213e-07],

[0.49411031, 9.799173e-08],

],

),

"Berest 2017 7.8": (

7.8,

"P",

[

[0.19575886, 2.2285256e-07],

[0.19575886, 9.505469e-08],

[0.19754389, 2.5947583e-07],

[0.19754389, 2.647936e-08],

[0.39379426, 4.9162047e-07],

[0.39738509, 6.801413e-08],

[0.59247161, 4.0957628e-07],

[0.59247161, 5.7241269e-07],

[0.59787408, 1.0735864e-07],

[1.0591736, 1.11804208e-06],

],

),

}Parameters

This set of parameters gives a good fit with the experimental data. The grain size is a bit larger than the usual grain size of roughly 1 cm.

A1 = 0.18 # d^-1

Q1 = 54e3 # kJ / mol

A2 = 6.5e-5 # m^3 K d^−1 # noqa: RUF003

Q2 = 24.5e3 # kJ / mol

dGrain = 5e-2 # m

sref = 1.0 # MPa

def BGRa(sig, T):

return A1 * np.exp(-Q1 / (8.3145 * (273.15 + T))) * np.power(sig / sref, 5.0)

def PLLC(sig, T):

return A1 * np.exp(-Q1 / (8.3145 * (273.15 + T))) * np.power(

sig / sref, 5.0

) + A2 * np.exp(-Q2 / (8.3145 * (273.15 + T))) * sig / sref / np.power(

dGrain, 3

) / (

273.15 + T

)Simulation and plot

The experimental data is compared against the model results (analytically and numerically)

lo_stresses = np.array([0.2e6, 0.6e6])

hi_stresses = np.array([2e6, 10e6])

Exps = {

7.8: ("blue", lo_stresses),

14.3: ("orange", lo_stresses),

25: ("lime", hi_stresses),

60: ("red", hi_stresses),

100: ("gray", hi_stresses),

200: ("mediumpurple", hi_stresses),

}

fig, ax = plt.subplots(1, 1, figsize=(8, 6))

ax.set_xlabel("$\\sigma_\\mathrm{ax}$ / MPa")

ax.set_ylabel("$\\dot{\\epsilon}_{zz}$ / d$^{-1}$")

ax.set_xlim(0.15, 30)

ax.set_ylim(1e-15, 1e1)

ax.grid(visible=True, which="both")

points = {"pt0": (1.0, 1.0, 1.0)}

sigs = np.logspace(-1, 2, 100)

for temp, (col, stresses) in Exps.items():

# plot analytical curves

if temp >= 25:

ax.plot(sigs, BGRa(sigs, temp), color=col, ls="--")

ax.plot(sigs, PLLC(sigs, temp), color=col, ls="-")

# simulation in ogs and plot results

eps_dot = []

ogs_model.replace_parameter_value("T_ref", str(temp + 273.15))

for stress in stresses:

ogs_model.replace_parameter_value("sigma_ax", str(-stress))

ogs_model.write_input()

# hide output

with contextlib.redirect_stdout(None):

ogs_model.run_model(

logfile=f"{out_dir}/out.txt", args="-m " + f"{data_dir}/Mechanics/PLLC/"

)

pvdfile = vtuIO.PVDIO(f"{prj_name}.pvd", dim=3)

eps_zz = pvdfile.read_time_series("epsilon", points)["pt0"][:, 2]

eps_zz_dot = np.abs(np.diff(eps_zz)) / np.diff(pvdfile.timesteps)

# omit the first timestep

eps_dot += [np.mean(eps_zz_dot[1:])]

ax.loglog(1e-6 * stresses, eps_dot, "o", c=col, markeredgecolor="k")

# plot experimental data points

for _Ex, (temp, m, Data) in ExData.items():

stresses, eps_dot = np.array(Data).T

ax.loglog(stresses, eps_dot, m, c=Exps[temp][0])

# create legend

patches = [

mpl.patches.Patch(color=col, label=str(temp) + "°C")

for temp, (col, _) in Exps.items()

if temp >= 25

][::-1]

def addLeg(**args):

return patches.append(mpl.lines.Line2D([], [], **args))

addLeg(c="k", label="PLLC")

addLeg(c="k", ls="--", label="BGRa")

addLeg(c="w", ls="None", marker="o", mec="k", label="OGS")

addLeg(c="k", ls="None", marker="s", label="DeVries (1988)")

addLeg(c="k", ls="None", marker="^", label="WIPP CS")

addLeg(c="b", ls="None", marker="P", label="Bérest (2017) 7.8°C")

addLeg(c="orange", ls="None", marker="P", label="Bérest (2015) 14.3°C")

ax.legend(handles=patches, loc="best")

fig.tight_layout()

plt.show()

References

Zill, Florian, Wenqing Wang, and Thomas Nagel. Influence of THM Process Coupling and Constitutive Models on the Simulated Evolution of Deep Salt Formations during Glaciation. The Mechanical Behavior of Salt X. CRC Press, 2022. https://doi.org/10.1201/9781003295808-33.

Li, Shiyuan, and Janos Urai. Numerical Studies of the Deformation of Salt Bodies with Embedded Carbonate Stringers. Online, print. Publikationsserver der RWTH Aachen University, 2012. http://publications.rwth-aachen.de/record/211523/files/4415.pdf

This article was written by Florian Zill. If you are missing something or you find an error please let us know.

Generated with Hugo 0.122.0

in CI job 430699

|

Last revision: January 2, 2023